BHT-T5HJWF090AP25, 15%

AG/AR/AFP Coated TAC Film, with OCA

Description

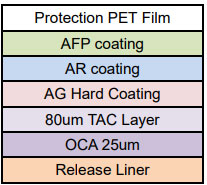

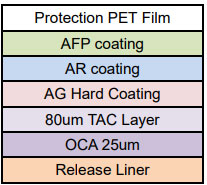

Coating Structure

Properties

Product Name

AG/AR/AFP Coated TAC Film, with OCA

Series Number

BHT-T5HJWF090AP25, 15%

Substrate Film

TAC Layer (80μm) + OCA 25um

Item

Result

Testing Method

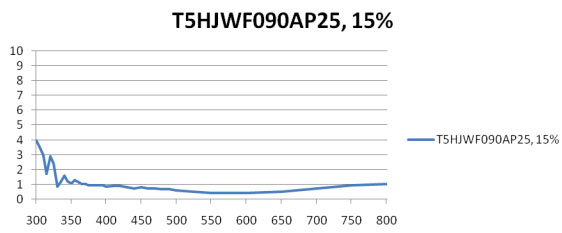

Reflectance

0.45%

UV-VIS-NIR Spectrophotometer

Absolute Reflectance(5 deg. incidence)

Total Luminous Transmittance

93.2 %

Apply to float glass (1mm). Haze meter

Haze

15%

Apply to float glass (1mm). Haze meter

Gloss 60°

60

Gloss meter

Cross-cut Tes

Good

Scotch Tape Peeling on AR Coated Layer

Pencil Hardness

3H

750g, JIS-K5600

Abrasion Resistance

○

Steel wool (#0000);500g, load 30 strokes

Adhesive force

13.9 N/25mm

JIS Z 0237basis (to glass)

Water contact angle

110°

60℃,95% humidity

Low/High Temp Durability

1000hrs pass

-30℃/ 80℃

Humidity+ Temp Durability

1000hrs pass

60℃,90% humidity

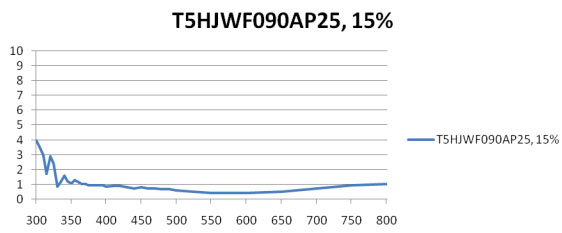

Optical Property (Transparence)

*The data indicated is the data measured in our company, but not the data our company guarantees.

Coating Structure

Properties

| Product Name | AG/AR/AFP Coated TAC Film, with OCA | |

| Series Number | BHT-T5HJWF090AP25, 15% | |

| Substrate Film | TAC Layer (80μm) + OCA 25um | |

Item |

Result | Testing Method |

| Reflectance | 0.45% | UV-VIS-NIR Spectrophotometer Absolute Reflectance(5 deg. incidence) |

| Total Luminous Transmittance | 93.2 % | Apply to float glass (1mm). Haze meter |

| Haze | 15% | Apply to float glass (1mm). Haze meter |

| Gloss 60° | 60 | Gloss meter |

| Cross-cut Tes | Good | Scotch Tape Peeling on AR Coated Layer |

| Pencil Hardness | 3H | 750g, JIS-K5600 |

| Abrasion Resistance | ○ | Steel wool (#0000);500g, load 30 strokes |

| Adhesive force | 13.9 N/25mm | JIS Z 0237basis (to glass) |

| Water contact angle | 110° | 60℃,95% humidity |

| Low/High Temp Durability | 1000hrs pass | -30℃/ 80℃ |

| Humidity+ Temp Durability | 1000hrs pass | 60℃,90% humidity |

Optical Property (Transparence)

*The data indicated is the data measured in our company, but not the data our company guarantees.