Home

/

Product Line

UV-Cut PET Film

BOTH HARVEST TECHNOLOGY CO., LTD. is one of the leading manufacturers of UV-Cut PET Film, and is highly regarded for its quality products. Our range includes Function Film (PET Film) in a variety of high-reliability, high performance, and industry standard. Our work is dedicated to the creation of progress with inspiring, innovative solutions and to a trusting partnership towards our customers and partners with common benefits. As a supplier and provider of complete solutions with locations in close proximity to our customers around the world, BOTH HARVEST TECHNOLOGY CO., LTD. is able to deliver comprehensive servicing for your UV-Cut PET Film in many other industries.

BHT-M8HV1299AP25

UV-Cut PET Film

Description

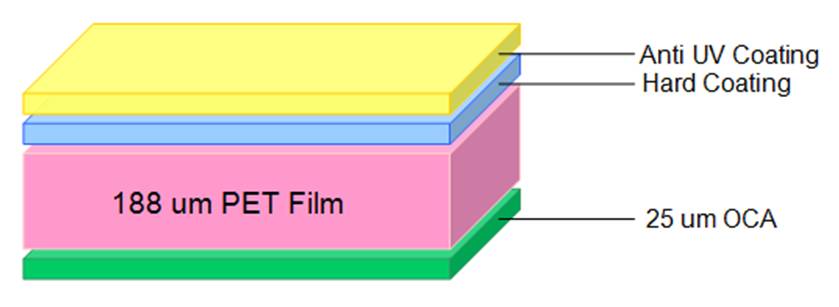

We develop this UV-Cut film for outdoor product. The UV-Cut layer to be applied on the top to reduce the UVA and UVB transparence together with Hard Coating on the surface. It certainly protects the inner product to be destroyed from the strong UV light. And the best product to have UV-cut function just with OCA lamination.

Product Structure

Application

Outdoor product

Properties

|

Dimension & Wavelength of the reflection

By Roll Type

1000mm Width * 200M Length / Roll

Everything we do as a company is based on reinforcing our position as the finest, most responsive solution provider in the UV-Cut PET Film industry. Our adherence to the timely and safe delivery of our fine quality UV-Cut PET Film has enabled us to maintain a long-lasting relationship with our existing clients. Our entire range is stringently checked on defined quality testing parameters, which is recommended by the industry. If you are interested UV-Cut PET Film, please feel free to contact us.